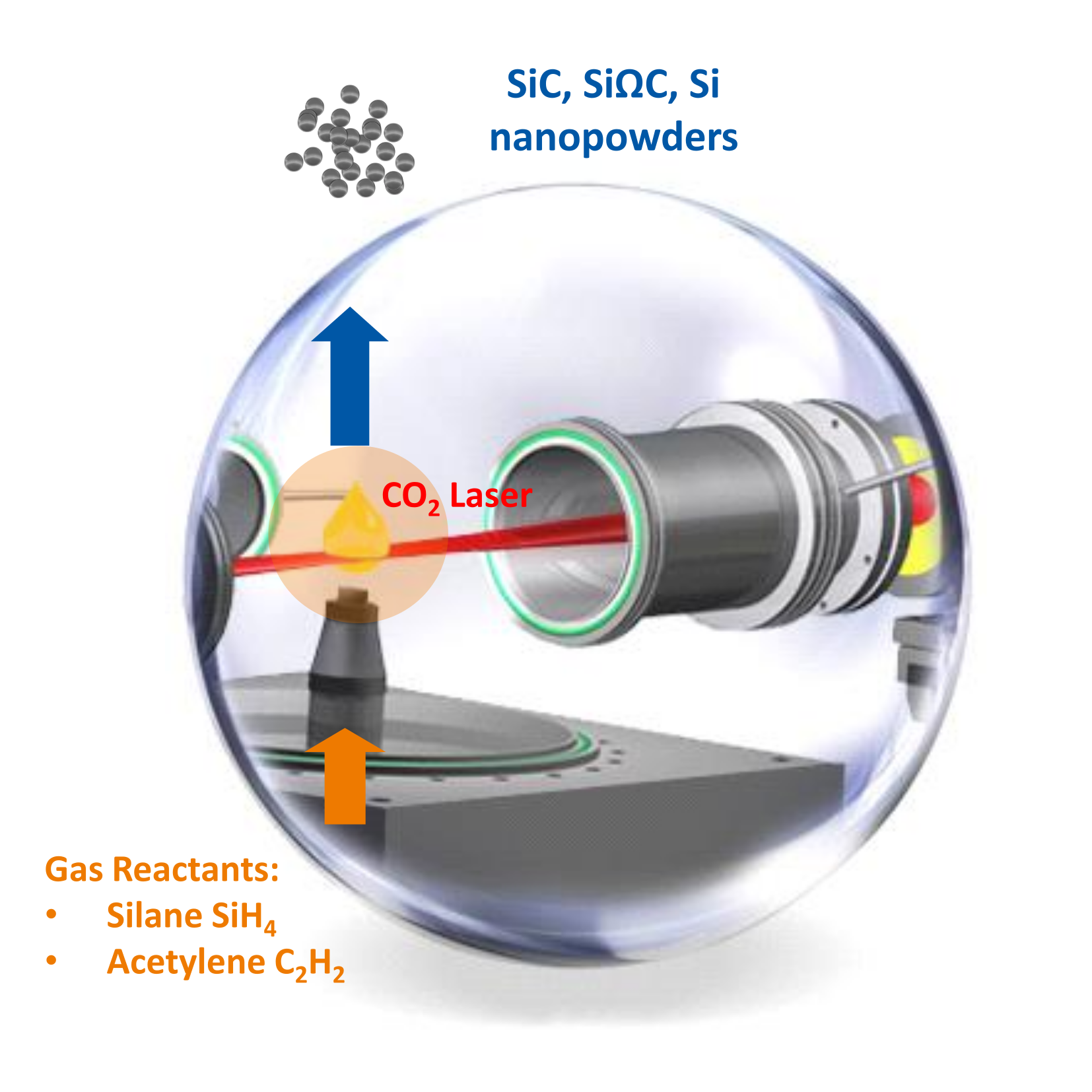

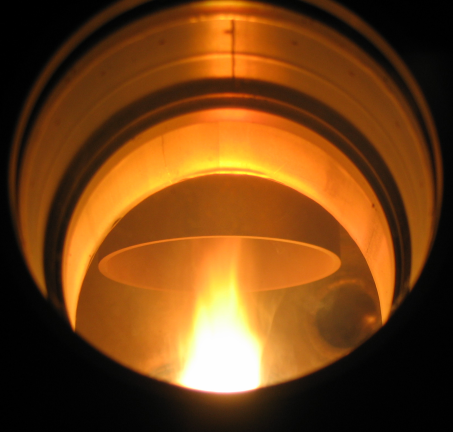

Synthesis method: Laser pyrolysis

Laser pyrolysis, the synthesis method of nanopowders

Used at Nanomakers, it can produce nanopowders at industrial scale.

Laser pyrolysis consists in decomposing in continuous way the gaseous materials by a laser beam. The know-how and the technology patented by CEA masteres the process at pilot scale. Nanomakers then bring this technology into the industrial scale to elaborate innovative nanopowder.