Li-ion batteries

Nano Silicon:

key component for Li-ion batteries anode

The growing demand for high-capacity, long-life batteries requires to look for new technologies. Improving the energy density of batteries, then its stability is one of the objectives targeted for the use of nano silicon as active material in anode.

Market needs

Carbon coated Silicon nanopowders for more autonomy

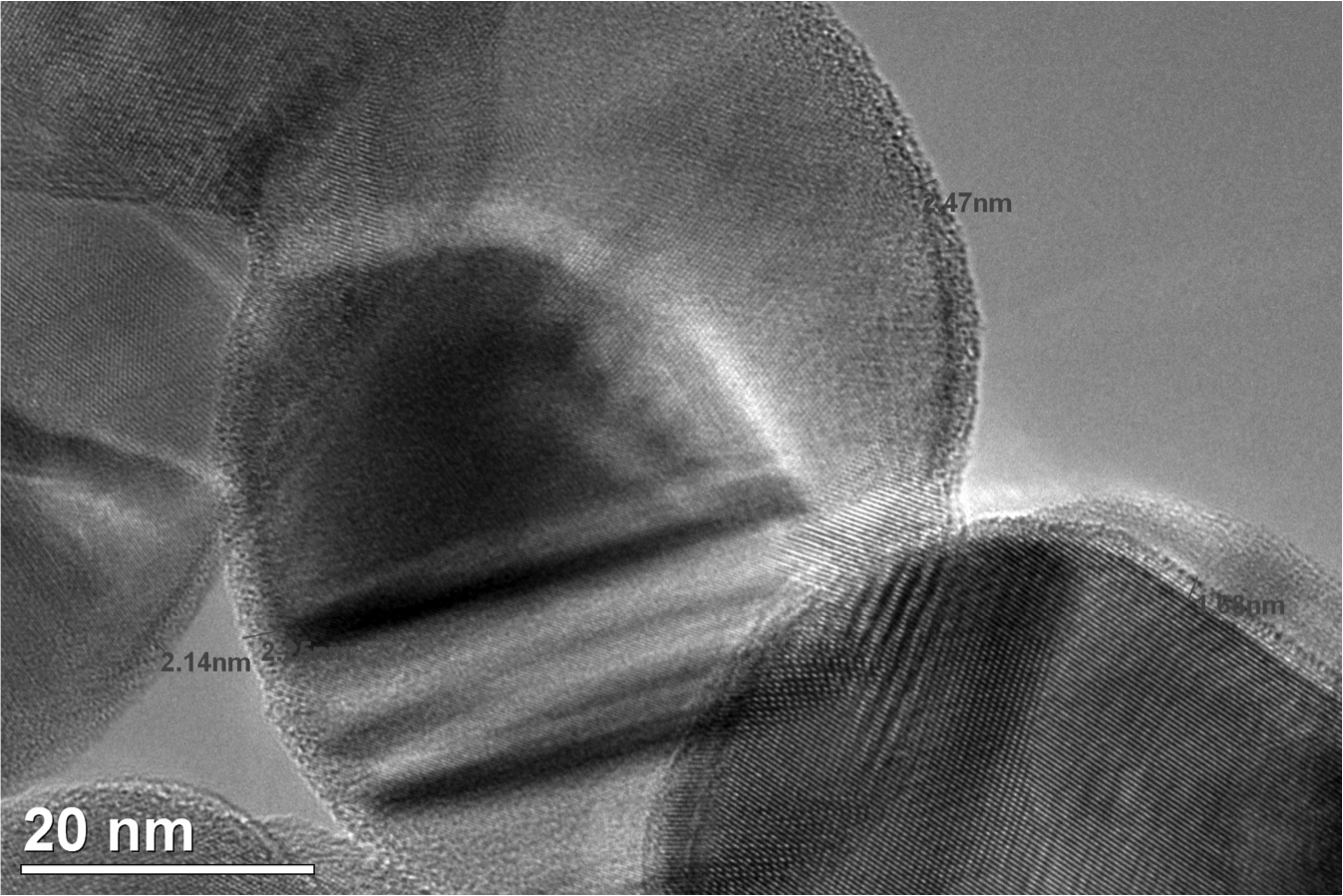

In Li-ion batteries, storage capacity of silicon is 10 times greater than graphite, the main anode material in use in Li-ion batteries (3576 mAh/g again 372 mAh/g). However, the use of Silicon is limited by two big constraints: its fracturation during the insertion of Li ions and its oxidation during the cycling. Nanomakers silicon nanopowders make it possible to bypass these constraints. Indeed, Nanomakers has developed and patented the carbon-coated silicon (SiΩC) in order to allow the use of Silicon inside Li-ion batteries and then to optimize their performances.

Contribution of NMSiΩC

Carbon coated Silicon, essential component

Nanomakers is offering carbon coated silicon nanopowders (SiΩC) as essential component which will boost the energy density of the anode in Li-ion batteries.

Advantages of carbon coating on Si nanopowders are:

Protect Si from direct contact with electrolyte

Improve the affinity of nano-Si with graphite and other anode components such as binders or conductive additives

Ease the dispersion of nano-Si in the graphite matrix

Facilitate the stability of the SEI layer

Advantages of the SiΩC in the anode of the Li-ion battery:

Significant increase in energy capacity (mAh/g) by mixing our nano-SiΩC with other common components of the anode (graphite, binders, carbonated additives, etc…)

Significant improvement in specific energy (Wh/kg) and in energetic density (Wh/L), which are the key indicators of battery performances

Compatible with the fast charging of the battery

Development of the composite Silicon / Carbon

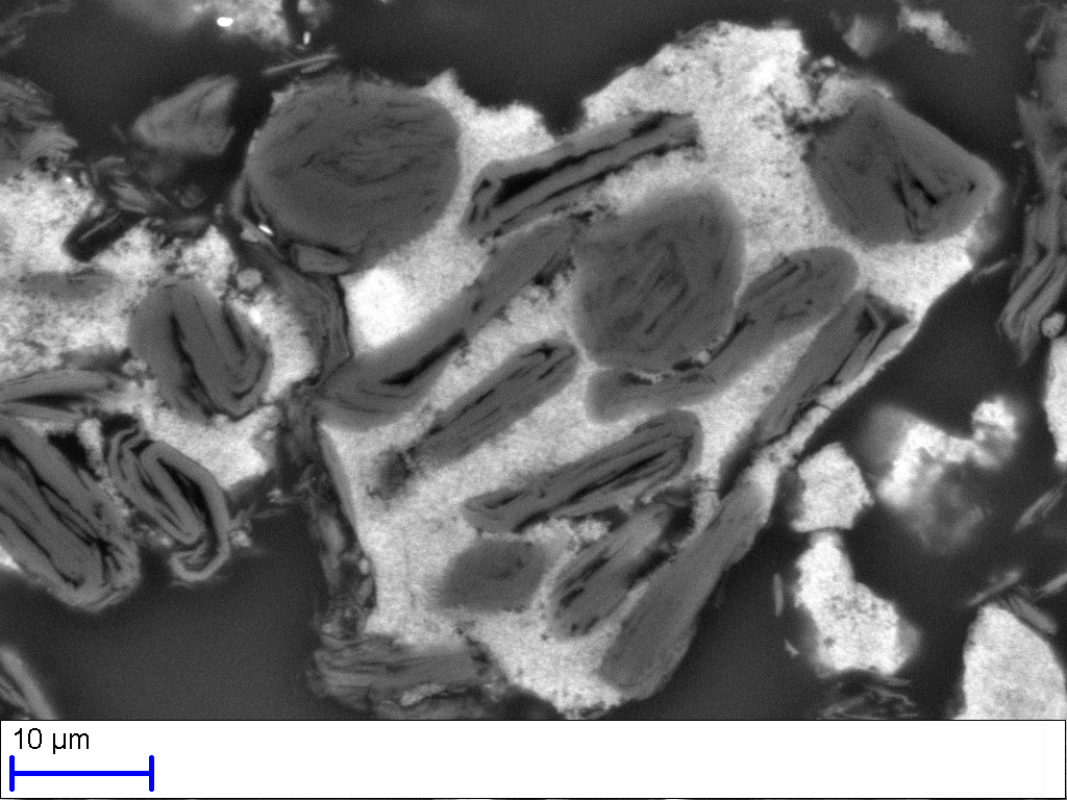

Composite Silicon / Carbon to facilitate the integration

Nanomakers also develops material formulations to make Silicon / Carbon composite. This alternative solution of our Silicon nanopowders can facilitate the integration of silicon inside the current battery manufacturing technologies and improve the capacity retention.

Advantages of Silicon / Carbon composite inside anode of Li-ion batteries:

Documentations

Sur nos solutions à l’application des batteries Lithium-ion

Around the topic

Product page:

Pages in the website:

Li-ion batteries electrode preparation

Documentation :