Aerospace

Reinforce the thermomechanical properties of CMC

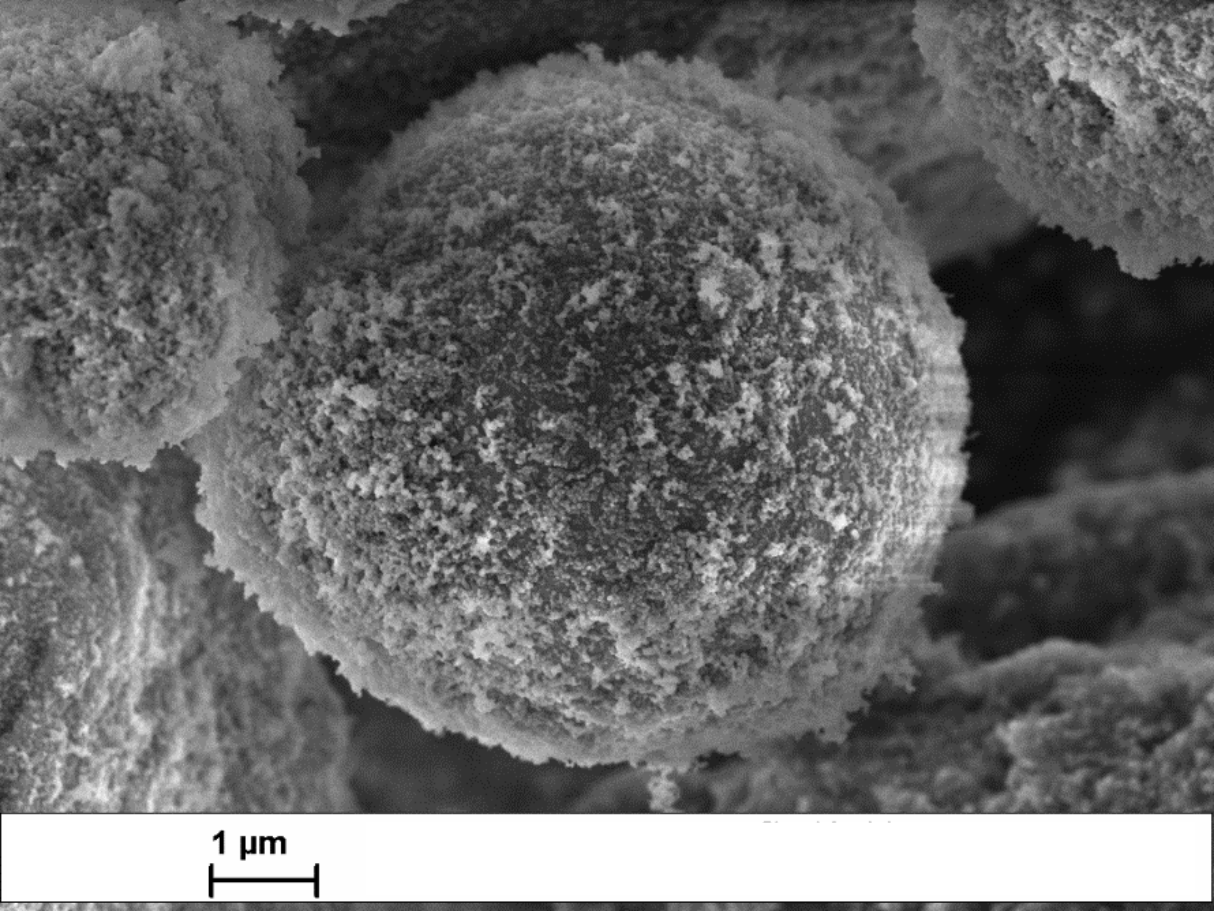

thanks to Silicon Carbide nanopowders

Reinforcing additives for CMC

The nano SiC can be used as reinforcing agent for the manufacturing of Ceramic Matrix Composites (CMC), especially SiC/SiC type.