Applications development

Projets & conseils pour développer des applications

Customized technical trials

Nanomakers has developed various technical skills through numerious research projects aiming at answering its customers’ needs.

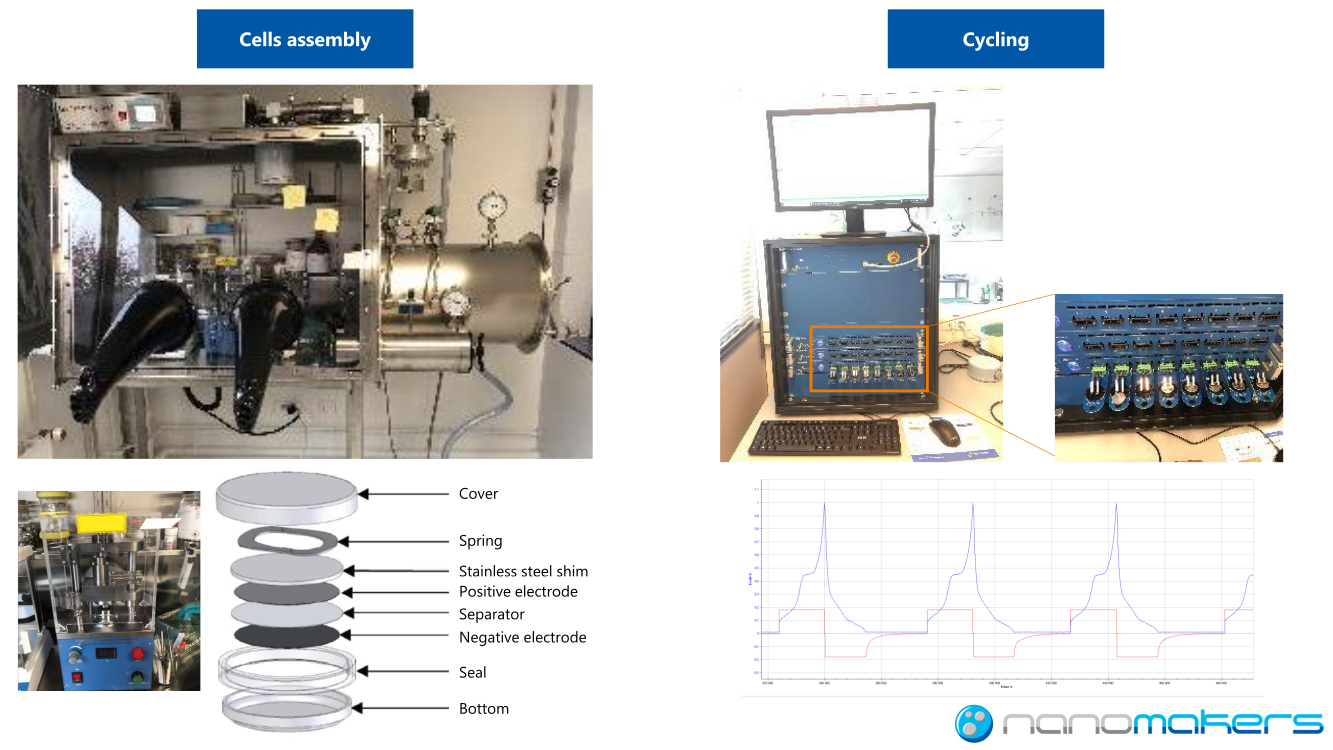

Preparation of electrodes and cells of Li-ion batteries

Cell preparation

Nanomakers has a long experience in anode formulation and has its own equipments to make and test electrodes.

We develop our own formulation of silicon based anode by adding our nano Si. Our R&D team can also adapt the anode preparation according to customers’ formulations.

Possible application:

Production optimization:

Le projet DEBIMAX, financé par l’UE, vise à mettre sur le marché un nouveau matériau d’anode pour les batteries lithium-ion. Le silicium enrobé de carbone peut remplacer en partie le graphite naturel utilisé actuellement dans les batteries. Déjà disponible pour l’électronique portable, ce nouveau matériau peut tripler les capacités. De plus, il est rentable et peut être disponible à grande échelle pour le marché automobile de masse. Ce produit a des performances uniques dans les anodes de batterie Li-ion.

Le projet Debimax de Nanomakers a montré la possibilité d’augmenter la production de 70 à 100% par ligne de production pour son nanosilicium breveté. De plus, les spécifications du produit ont été optimisées.

Illustration photo: Old (left) and new Debimax powder collectors (right)

Ce projet a reçu les subventions venant du programme de recherche et d’innovation Horizon H2020 de l’Union européen, avec l’accord de subvention No 880701. Ce projet a été accordé dans le cadre de l’appel à projet « SME-2 – SME instrument phase 2 ».

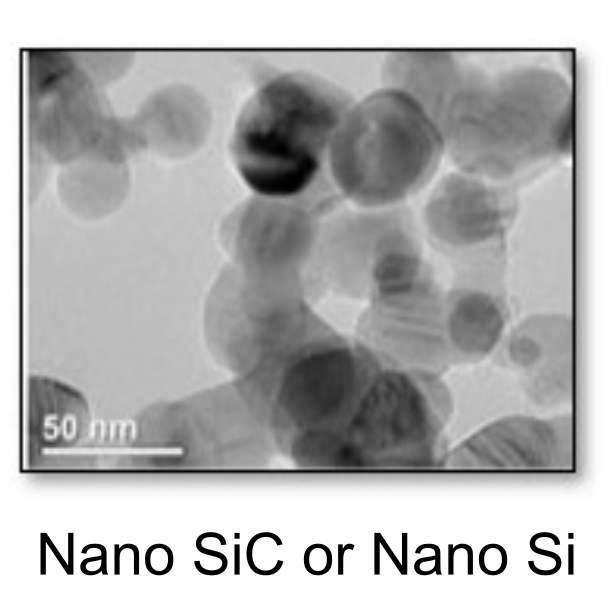

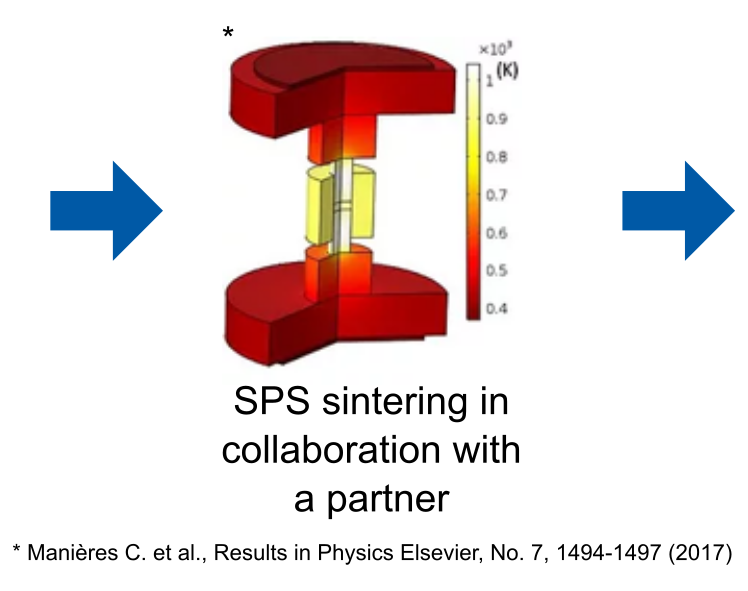

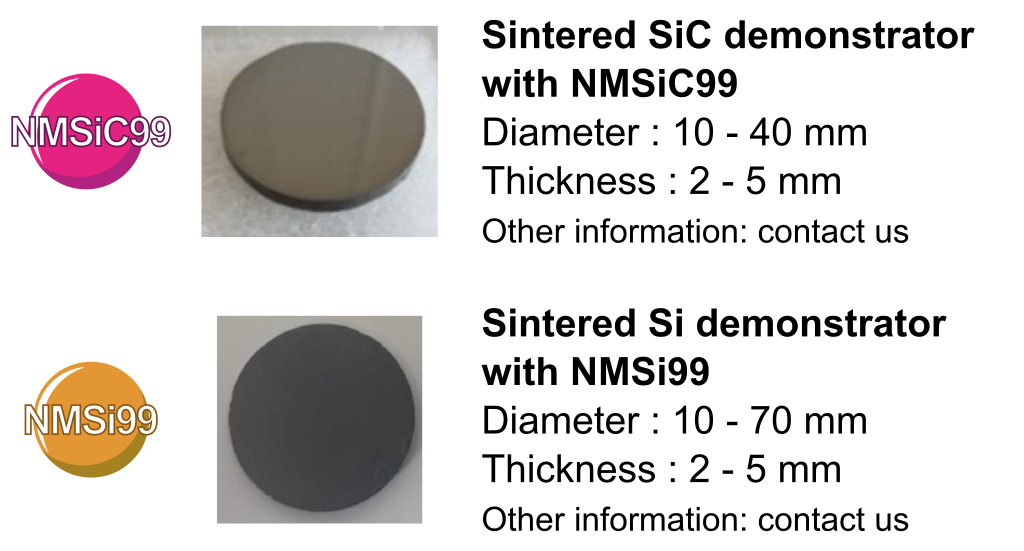

Sintering SiC and Si nanopowders

By Spark Plasma Sintering (SPS)

Nanomakers work on the sintering of SiC and Si nanopowders to obtain sintered parts which will be interested in semiconductor or aerospace sector. We have some development projects which aim to get sintered parts with variable densities (from 40% to >99%), with or without sintering additives.

Realization of colloidal slurries

Slurries containing nanoparticles

We collaborate with our customers to establish their specifications in order to make adapted slurries to their needs. This goes by defining data such as:

the solid loading ratio

the viscosity of final slurry

the stability target

We exchange with our customers to define dispersion trials according to their problems and their constraints. This goes by selecting options such as:

the trial at lab scale then semi-pilot

the choice of solvents (water based or organic)

the use of additives (stabilizers, dispersants, …)

Exemple of prepared slurry

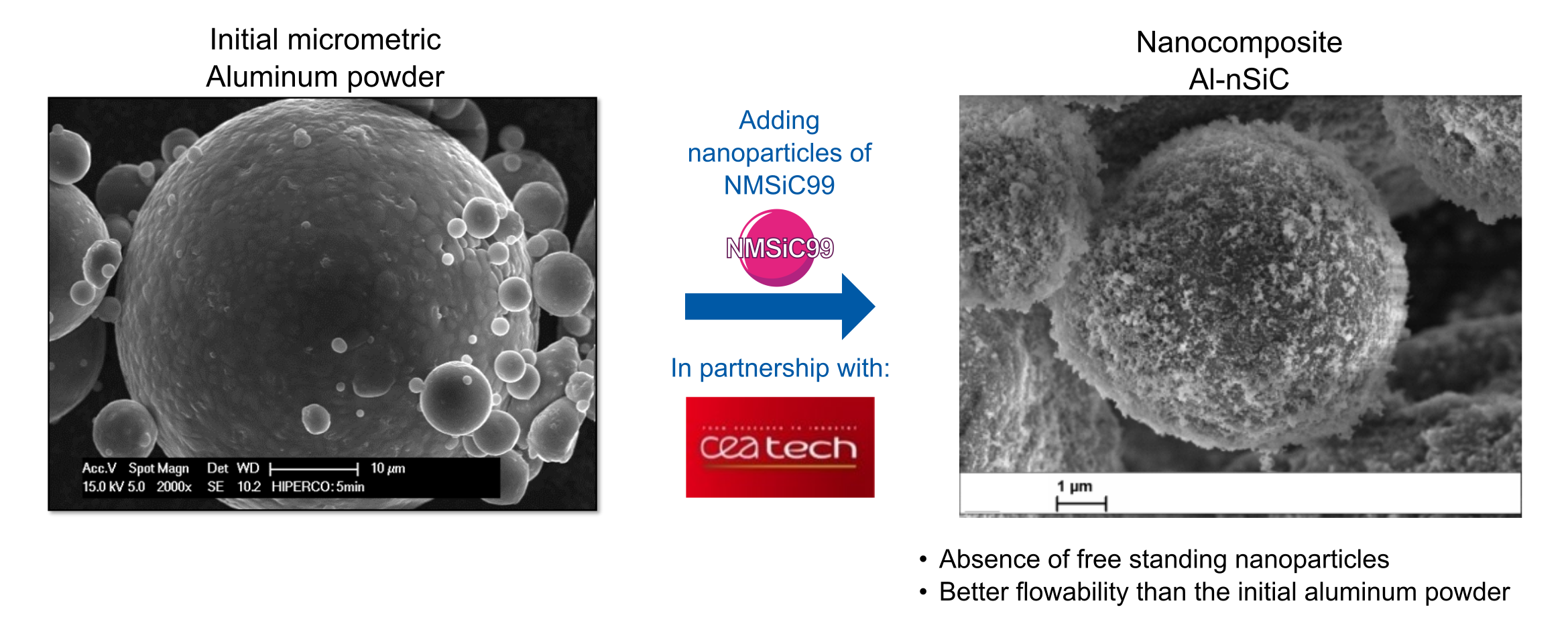

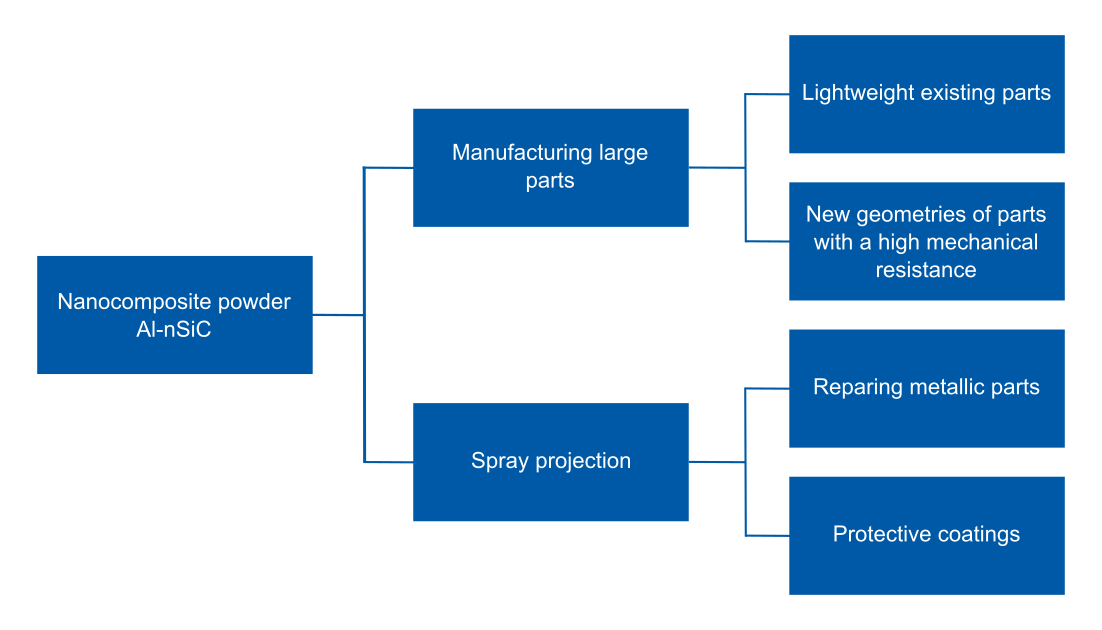

The nano SiC, reinforcing agent for metallic matrices

Technical challenges answering market needs

Production of lightweight parts for high added values markets

Improving mechanical proprerties of aluminum alloys using nano-reinforcement

Around the topic

Summary of the page:

Li-ion batteries electrode preparation

Sintering SiC and Si nanopowders

Realization of colloidal slurries

The nano SiC, reinforcing agent for metallic matrices